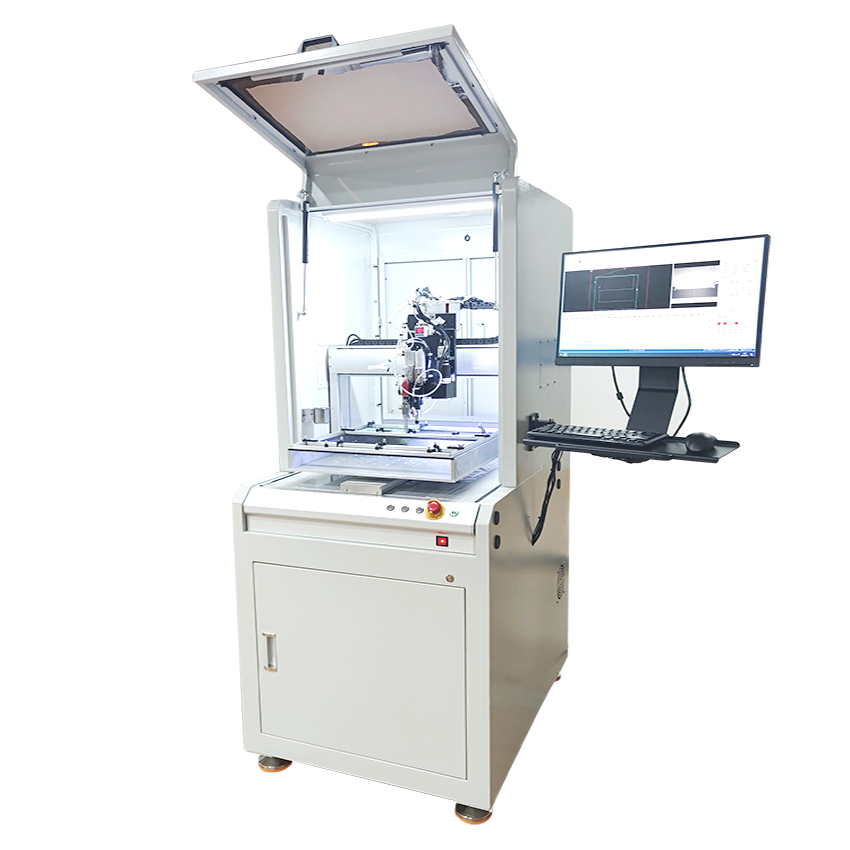

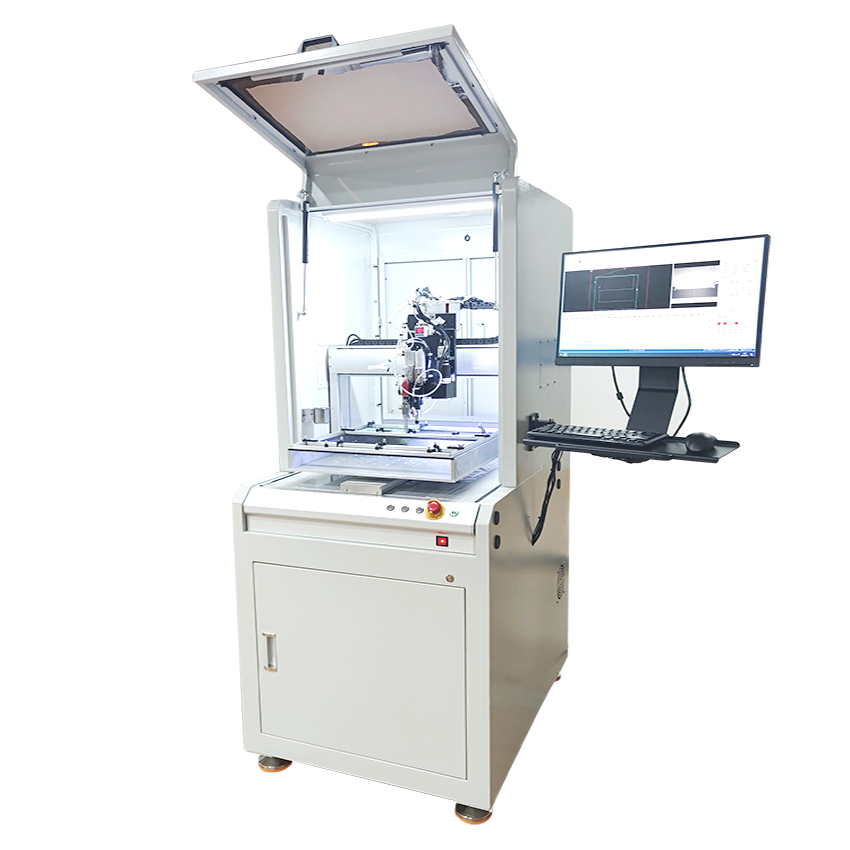

In the field of modern industrial manufacturing, the coating process is a key link to ensure the quality and performance of products. The offline visual coating machine, with its advanced technical concept and innovative design, has brought about significant changes and improvements to coating operations, demonstrating unique advantages in multiple aspects.

The core advantage of the offline visual coating machine lies in its high-precision coating effect. This device is equipped with an advanced visual recognition system, which is capable of positioning and contour scanning of the coated object. By capturing product details through high-definition cameras and combining them with high-precision image processing algorithms, micron-level coating accuracy control can be achieved even for workpieces with complex shapes and tiny sizes. This high precision not only ensures the uniformity of the coating, avoiding product quality issues caused by uneven coating, but also effectively saves coating materials and reduces production costs.

The operational capacity of the equipment should not be underestimated either. The offline visual coating machine does not need to be linked with the production line in real time and can perform coating operations independently. This enables it to flexibly adjust the production plan and quickly switch the coating program when dealing with products of different batches and specifications. Meanwhile, the equipment is equipped with a high-speed and stable motion control system, combined with an intelligent path planning algorithm, which significantly reduces the coating time, increases the output per unit time, effectively enhances production efficiency, and meets the demands of large-scale production in enterprises.

In terms of cost control, offline visual coating machines also perform exceptionally well. Due to its high precision, it reduces material waste, and the equipment operates stably with a low failure rate, effectively controlling maintenance costs. In addition, this equipment is easy to operate. Workers who have received simple training can master the operation skills proficiently, reducing the labor costs of enterprises. Meanwhile, the offline operation mode reduces the reliance on the overall layout of the production line. Enterprises can flexibly arrange the equipment positions according to actual needs, optimize the production space, and further save the cost of site usage.

The offline visual coating machine also has good compatibility and scalability. It can adapt to a variety of different types of coating materials, such as adhesives, inks, coatings, etc., and the coating process parameters can be adjusted according to product requirements to meet diverse production needs. With the continuous development of technology, more functions can be endowed to the equipment through software upgrades, hardware expansion and other means, enabling it to keep up with the industry development trends and continuously create value for enterprises.

Offline visual coating machines, with their advantages of high precision, efficiency, low cost and good compatibility, occupy an important position in the industrial coating field, providing strong support for enterprises to improve product quality and enhance market competitiveness.

The above content demonstrates the advantages of offline visual coating machines from multiple dimensions. If you still want to know about its application cases in specific industries or compare it with other coating equipment, please feel free to tell me at any time.