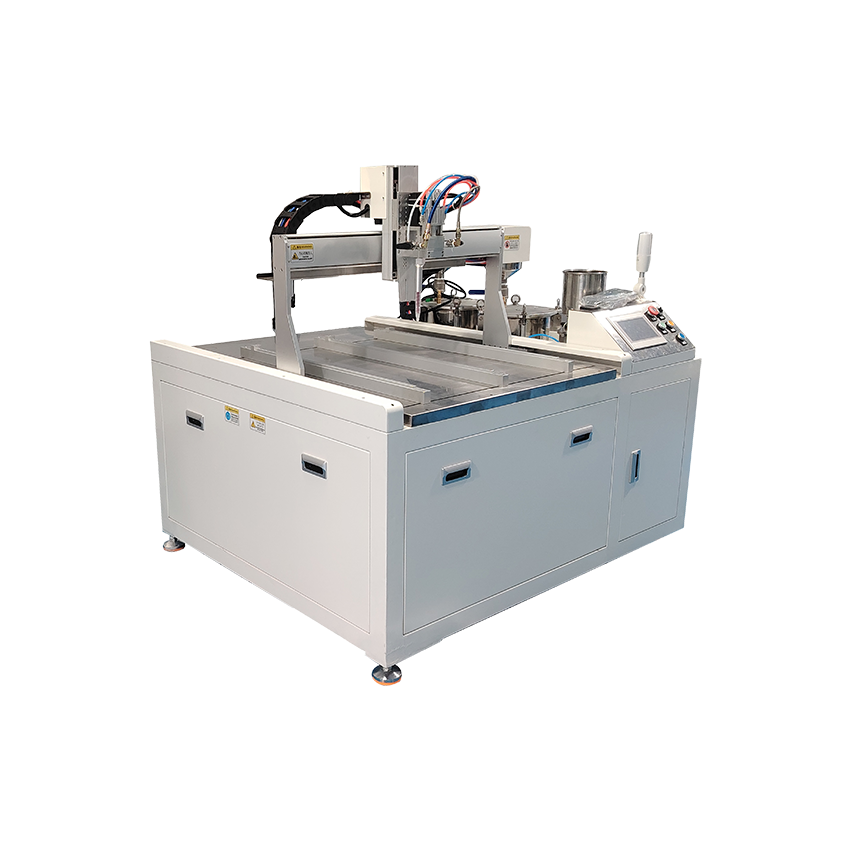

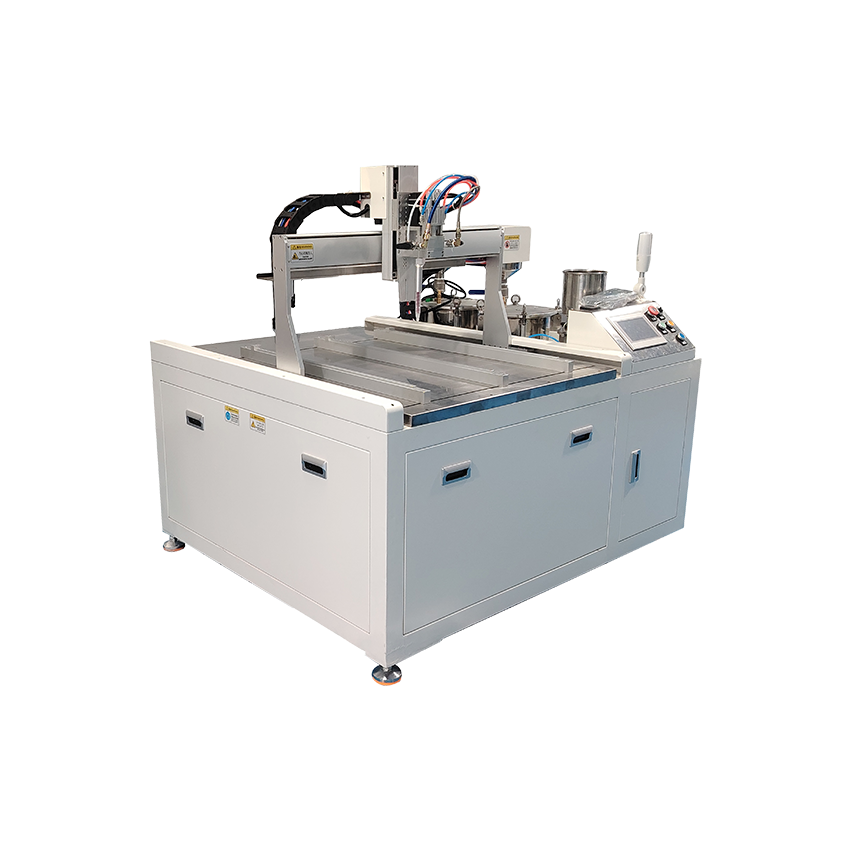

In the field of electronic equipment manufacturing, the potting process plays a significant role. It not only enhances the performance of electronic components and extends the service life of equipment, but also strengthens the stability and reliability of products. As the core equipment for realizing glue injection, the glue injection machine is widely used in the production process of various electronic components.

Printed Circuit Board (PCB

Printed circuit boards are the core components of electronic devices, and potting machines play a crucial role in their manufacturing process. In terms of the protection and reinforcement of PCBS, potting compound can effectively prevent moisture, dust, chemical substances, etc. from eroding the circuit board, avoid short circuits and corrosion, and improve the stability of the circuit board. The potting machine can accurately apply glue to specific areas, such as around the chip and at the solder joints, ensuring that the circuit board can still operate stably in harsh environments. In addition, during the repair process of PCBS, the potting machine can also be put to use to repair the damaged circuit parts and restore their normal functions.

Integrated circuit (IC) chip

IC chips are the "brain" of electronic devices, and their performance and reliability are of vital importance. By potting IC chips, the potting machine can effectively protect the chips from the influence of the external environment, enhance their mechanical strength and improve their heat dissipation performance. For some chips, such as mobile phone processors and computer cpus, the potting machine can adopt a high-precision dispensing method to apply an appropriate amount of glue on the surface or pins of the chip, ensuring a firm connection between the chip and the substrate and stable signal transmission.

Sensor

Sensors are the key components for electronic devices to perceive external information, and their performance directly affects the functions of the devices. The potting machine can perform potting on sensors, which can enhance their waterproof, dustproof and shock-proof performance and extend their service life. Take the acceleration sensor and gyroscope sensor in mobile phones as examples. The glue filling machine can evenly apply glue between the sensor's casing and internal structure, fill the gaps, reduce the impact of vibration on the sensor's accuracy, and ensure that the sensor can accurately perceive external signals.

Connector

Connectors are responsible for connecting various components in electronic devices to ensure the smooth transmission of signals and currents. The potting machine potting the connectors can enhance the sealing performance of the connectors, prevent oxidation and corrosion, and improve the reliability of the connection. In some electronic devices with high stability requirements, such as aerospace equipment and communication base stations, potting machines can effectively reduce contact resistance and signal interference by potting connectors, ensuring the normal operation of the equipment.

Display screen

In the manufacturing process of display screens, potting machines are also indispensable. In the frame and backlight module of the display screen, the potting machine can evenly apply the sealant at the corresponding positions to prevent dust and moisture from entering the interior of the display screen and affecting the display effect. In addition, for some flexible display screens, the potting machine can also reinforce them to enhance the flexibility and durability of the display screens.

Potting machines have extensive applications in the manufacturing of electronic equipment. From core PCBS and chips to various components such as sensors, connectors, and displays, potting machines can play a significant role in helping the electronic equipment manufacturing industry produce higher-quality products.