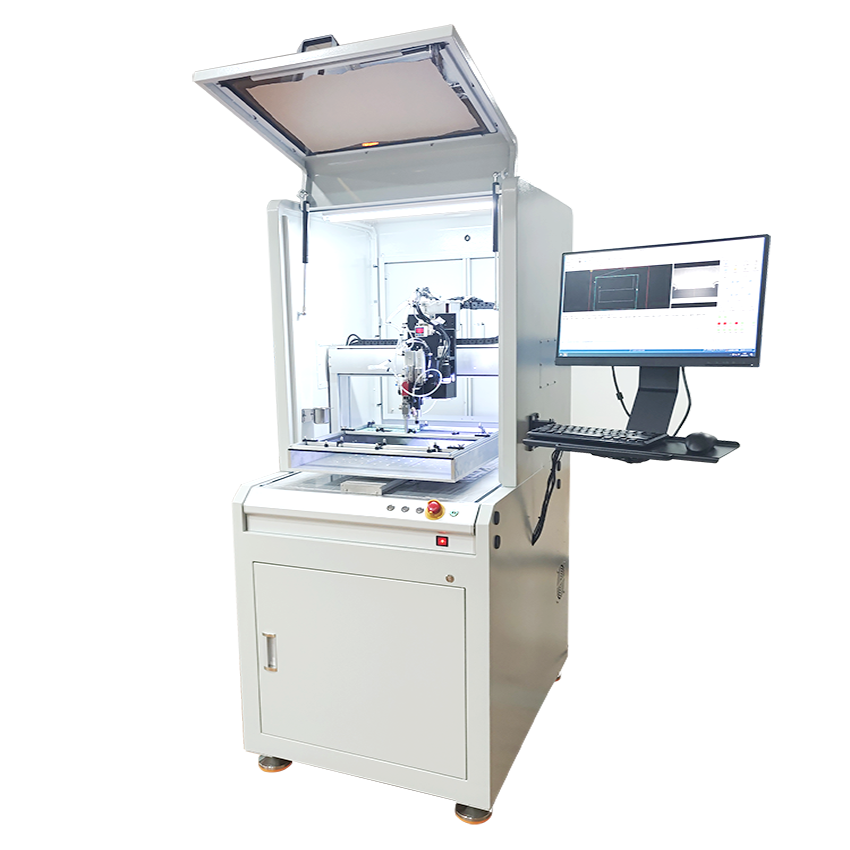

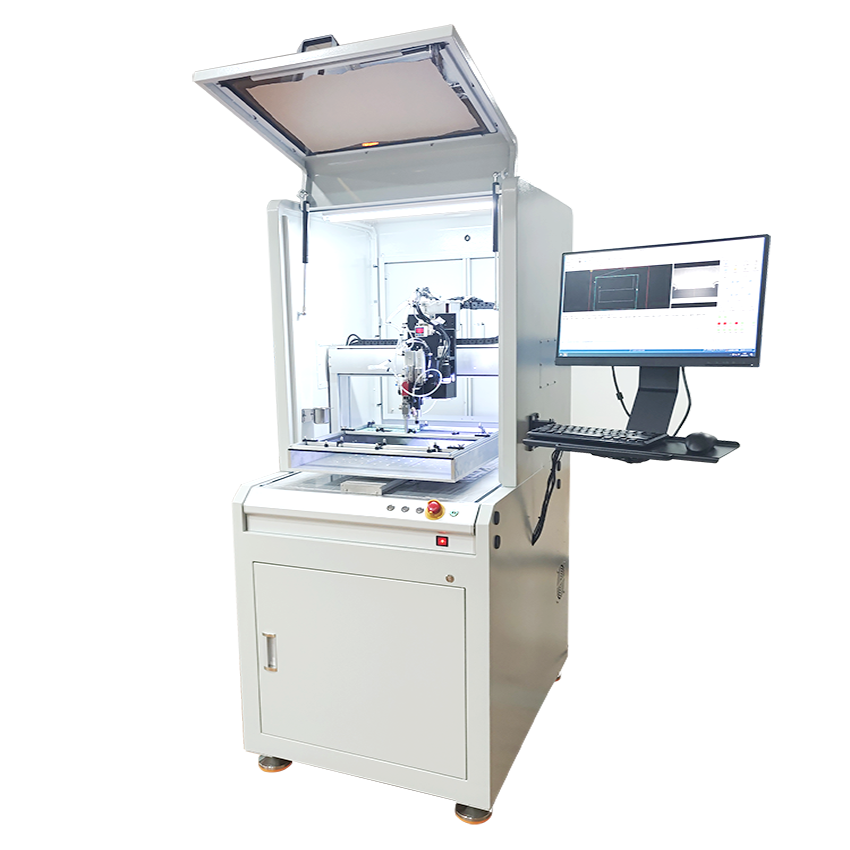

The visual following coating machine, with its high-precision visual system, achieves accurate coating of various workpieces. As the "core sensory organ" of the equipment, the operation status of the visual system directly affects the quality and efficiency of the coating. Proper daily maintenance of the vision system can ensure the stable operation of the equipment, reduce the failure rate and extend the service life of the equipment. Below, we will introduce the key points for the daily maintenance of the visual system of the visual following coating machine.

Cleaning of lenses and cameras

Lenses and cameras are key components for the visual system to acquire images. The cleanliness of their surfaces is crucial to the clarity and accuracy of image acquisition. During daily maintenance, it is necessary to regularly use a dedicated lens cleaner and a lint-free cloth to gently wipe the surface of the lens. When wiping, follow the sequence from the center to the edge to prevent scratching the lens. At the same time, avoid using rough or corrosive cleaning tools to prevent damage to the lens coating. For the camera casing, it is also necessary to keep it clean to prevent dust, oil stains and other contaminants from entering the camera interior and affecting the image acquisition effect. It is recommended to conduct a comprehensive lens and camera cleaning at least once a week.

Calibration of visual system parameters

The parameter Settings of the vision system are directly related to the recognition accuracy of the workpiece. As the device is used, some parameters may shift due to environmental changes or hardware aging, resulting in visual recognition errors. Therefore, it is necessary to calibrate the parameters of the visual system regularly, such as exposure time, white balance, resolution, etc. The vision system is calibrated by using standard test boards to ensure that it can accurately identify the shape, size and position of the workpiece. When changing different types of workpieces or coatings, it is also necessary to appropriately adjust the parameters of the visual system according to the actual situation to achieve the best recognition effect.

Data backup and software update

The data and software in the visual system are important guarantees for achieving accurate identification and control. Regularly backing up key data in the vision system, such as workpiece recognition models and parameter Settings, can prevent production disruptions caused by data loss. Meanwhile, pay attention to the software update information released by the equipment manufacturer and update the software version of the vision system in a timely manner. New software versions usually fix known vulnerabilities, optimize algorithms, and enhance the performance and stability of the vision system. When performing software updates, be sure to follow the operation guidelines provided by the equipment manufacturer to ensure a smooth update process.

Hardware inspection and maintenance

In addition to the maintenance of software and data, hardware inspection is equally important. Regularly check whether the connection lines of the vision system are loose or damaged to ensure stable signal transmission. At the same time, check whether the installation position of the camera has shifted. If there is a shift, make adjustments in time to ensure that the camera can accurately capture the workpiece. For other hardware components in the vision system, such as light sources and image acquisition cards, regular inspections are also necessary to ensure their normal operation.